Why Robot Hands Won’t Take Over the Warehouse Anytime Soon

Will robot hands take over the warehouse? Of course not! Vacuum …

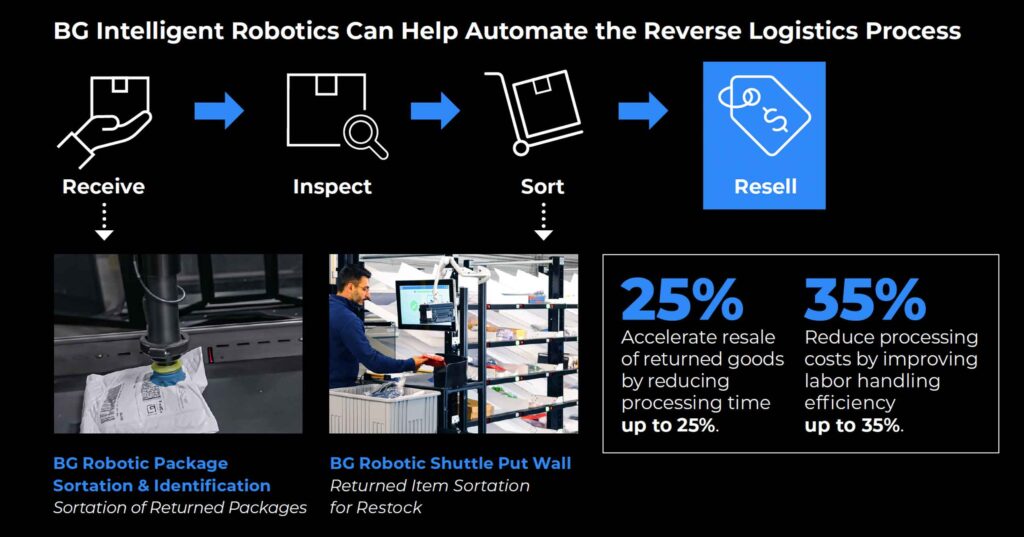

The new AI-enabled Reverse Logistics solution helps eCommerce retailers and 3PLs accelerate resale of returned goods by reducing the processing time up to 25% with robotic automation

The speed with which eCommerce vendors delivered all our goods this holiday season put smiles (mostly) on millions of faces—both ours and those of vendors. But for vendors, there’s often a steep price: returns. Close to 30% of all eCommerce orders are typically returned by consumers. Projections indicate that by the end of January 2022, consumers will return approximately $120 billion of goods following the holiday season.

Keeping consumers happy while preventing returns from eating into profitability is the daily challenge of reverse logistics, an intensive, particularly labor-bound process that basically reverses the fulfillment process. With additional challenges like non-uniform packaging of items returned by consumers and the extra step of goods inspection before items can be returned to inventory for l resale (or other dispensation). Think fulfillment but with more quirks and exceptions.

This makes those “free and easy” returns for customers anything but for eCommerce retailers and 3PLs that handle returns. Free, no-hassle returns are a major driver of eCommerce growth, particularly in categories such as apparel, footwear, electronics, and luxury items, and a differentiator in the customer experience. However, the average cost of an e-Commerce return, regardless of item value, ranges from $20.75 to $45.25, when factoring in the costs of transportation, processing and markdowns/liquidation to resell. To reduce the impact of these costs, retailers need to focus efforts on increasing the resale of previously purchased goods. All of this cuts into the retailers’ profitability.

But it doesn’t have to be so painful —not anymore. The priority for eCommerce retailers today after reducing returns from happening (which may be a pipe dream, to some extent, given consumers’ habituation to easy returns) is getting resellable merchandise back on shelves as fast as possible while optimizing labor utilization. No easy task.

By automating reverse logistics processes using AI-enabled robotics, eCommerce retailers can reduce the time to recirculate returned items back onto the shelf and optimize labor productivity, ultimately improving profitability. Follow this three-step approach:

Step 1: Deploy robotic automation to receive and bulk-sort returned packages. Robotically pick, identify, receive, sort, and containerize large assortments of eCommerce packages prior to inspection. Returns will move faster from Receiving to Inspection, the latter of which is now more efficient because you’ve already sorted the returns by brand, category, or other key business identifiers. Enjoy even more efficiencies by, for example, automatically triggering return package receipt confirmation without having to touch the individual packages. Any time you can avoid or reduce manual handling of returned packages is a big win, obviously. AI-enabled robotics broadens the opportunity.

Step 2: Automate the return-to-inventory process. Next, robotic put wall systems streamline the sorting of individual items for fast restocking or other dispensation. Automated put walls have shown that this step can reduce sorting labor by up to 70%, improve individual item sorting throughput by up to 3X, and shorten the time to get goods back into inventory or moved to refurbishment up to 25% faster than manual processing.

Step 3: Optimize and fine-tune your new robotic returns workflow. This more than anything else can give you a competitive advantage over others who’ve discovered the transformational power of AI-enabled robotic automation for reverse logistics. Take advantage of the increasingly advanced robotic technology and systems-integration expertise available today to integrate best-in-class components into a solution that fits your reverse-logistics process to a T. Continual attention to workflow with data-driven analytics can help you get the maximum value when integrating automated and non-automated steps–for example, to minimize exception handling and other cost-sinks.

The more intelligence and responsiveness you can build into the steps above–this is where AI really comes in–the more you’ll change the equation for eCommerce returns and turn a negative into a positive.

Berkshire Grey, the leader in AI-enabled robotic solutions that automate supply chain processes, recently announced the availability of its solution for reverse logistics. The solution speeds up returns processing to get goods back into inventory or moved to refurbishment up to 25% faster than manual processing. In addition, the solution reduces processing costs by improving labor handling efficiency by up to 35%. Berkshire Grey’s Reverse Logistics solution includes its Robotic Product Sortation with Identification (RPSi) and Robotic Shuttle Put Wall (RSPW) systems, both of which are specifically configured to efficiently process returns. Both systems improve labor utilization and speed up the overall returns handling process to make returns less costly and ultimately more valuable to the sellers.

For more information on Berkshire Grey’s Reverse Logistics solution, download the solution brief here.

Will robot hands take over the warehouse? Of course not! Vacuum …

In a recent webinar, “Unlock $20M Savings with Superior Efficiency: Robotic …

With a strong foundation of AI-driven robotics and a mission to …

Contact the BG Fulfillment Automation Sales Engineering Team to Learn How to:

Call +1 (833) 848-9900

or connect using our form.