Why Robot Hands Won’t Take Over the Warehouse Anytime Soon

Will robot hands take over the warehouse? Of course not! Vacuum …

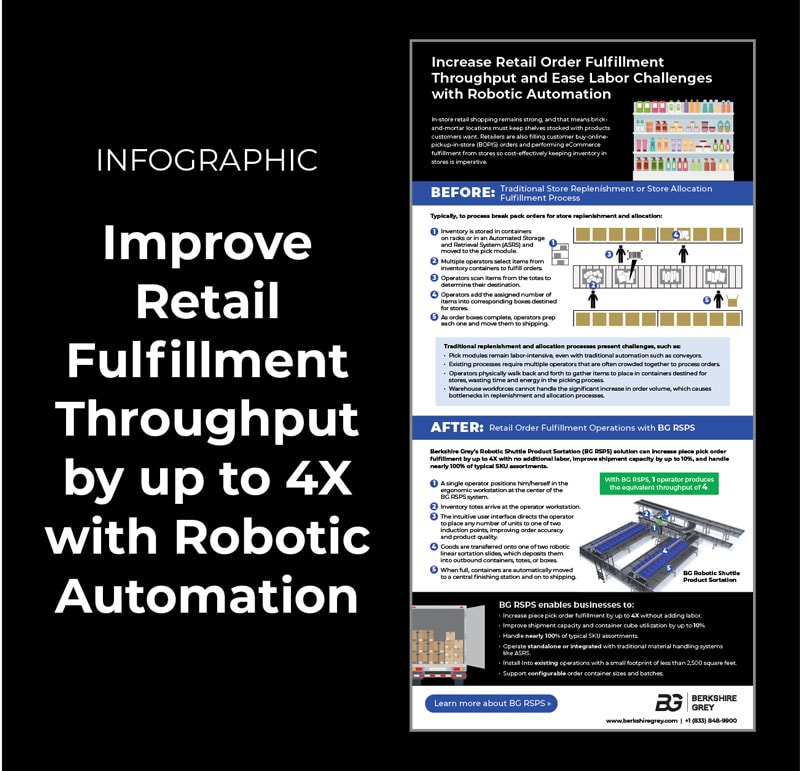

Robotic product sortation can help retail fulfillment centers increase piece pick order fulfillment by up to 4X, improve container cube utilization by up to 10%, and handle nearly 100% of typical SKU assortments.

Retail, grocery, and 3PL businesses strive to keep stores stocked with products customers want while also meeting demand for more online orders than ever before. Despite global eCommerce accounting for nearly 20% of retail sales, more than 80% of buying still occurs in physical stores. In many cases, retailers must maintain in-store inventory to not only address in-store shoppers but also to fill eCommerce orders directly from stores. These realities demand more efficient, cost-effective approaches to store replenishment and store allocation fulfillment processes in distribution centers

This week, Berkshire Grey announced the general availability of its Robotic Shuttle Product Sortation (BG RSPS) solution that can help retail, grocery, and other businesses significantly improve store replenishment and allocation order processes. BG RSPS is a fully integrated system powered by AI software that enables distribution centers to process more orders at existing facilities while requiring significantly less labor. BG RSPS enables retailers, grocers, and 3PLs to increase throughput, and drive growth despite labor shortages. Already deployed across major retailers, BG RSPS has the ability to:

Here’s how retailers and grocers can benefit from BG RSPS.

BG RSPS can perform tasks associated with store replenishment, split-case cross docking, and allocation order processing. Without a robotic automation solution, these processes require significant labor to complete the tasks needed to fulfill orders. Manual sorting operations are very labor-intensive, but even traditional semi-automated pick modules require more labor than the shuttle sortation approach. With BG RSPS, a single operator takes individual items or split cases from inventory containers and places them to induction points, and the system automatically sorts the goods into up to 60 outbound containers for shipment to stores. The result is a 4X boost in piece pick order processing along with an up to 10% increase in order container cube utilization.

The flexible footprint of BG RSPS lets retailers install stations wherever they have 2500 square feet of space, including on a mezzanine. As requirements change, retailers can scale throughput simply by adding orchestrated parallel systems without taking up significantly more space. Over the long term, robotic shuttle sortation systems provide an innovation pathway that delivers intelligent enterprise robotics — modular, flexible, and able to grow with each customer’s business.

An AI-driven sortation system also frees employees from having to walk back and forth, reducing worker fatigue and supporting social distancing protocols. Instead, workers use an ergonomic workstation, easing the strain of repetitive tasks and putting the products on induction points that allow the system to automatically sort the goods into store-bound containers. The BG RSPS system enables retailers to transform distribution operations into a competitive advantage while enabling increased throughput in the midst of the ongoing labor scarcity.

Will robot hands take over the warehouse? Of course not! Vacuum …

In a recent webinar, “Unlock $20M Savings with Superior Efficiency: Robotic …

With a strong foundation of AI-driven robotics and a mission to …

Contact the BG Fulfillment Automation Sales Engineering Team to Learn How to:

Call +1 (833) 848-9900

or connect using our form.