The Future of Warehouse Automation: A Deep Dive into Robotic Put Wall Systems

During our recent webinar titled “Automate and Accelerate: Replacing Pick-to-Light with …

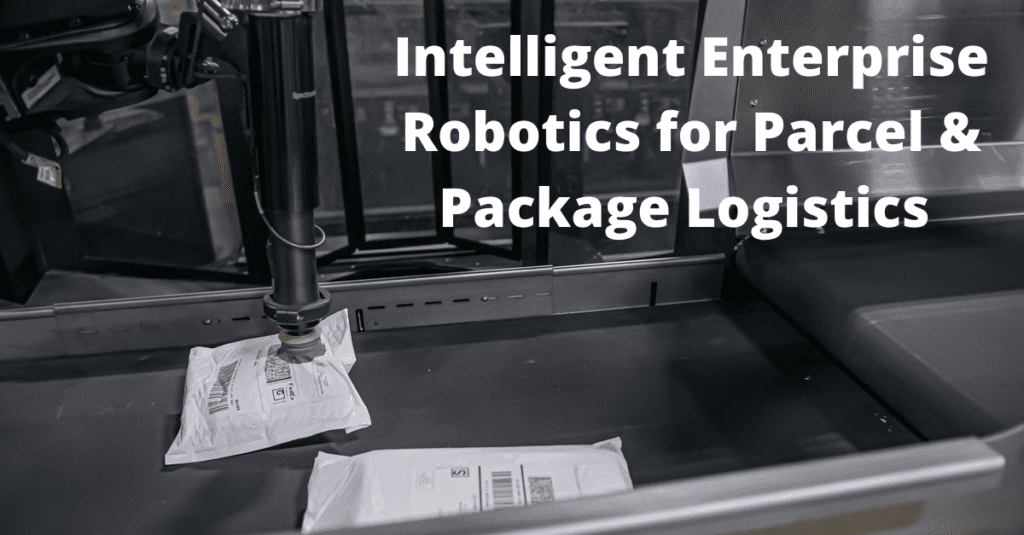

With higher volumes of smaller packages, carriers must find ways to process more orders and accelerate delivery.

For parcel and package logistics companies, timely and accurate delivery of items is mission-critical to business success.

That’s why carriers are looking for innovative robotic approaches to cost-effectively process and sort huge volumes of small packages and parcels through their networks, accelerating deliveries across regional and national locations. The volume growth for package shipping companies is occurring with their most expensive shipments — more frequent, small packages to customer locations. This is causing carriers to incur:

All carriers face increasing volumes of packages and growing customer expectations for faster delivery to many locations. Using Berkshire Grey Robotic Sortation, carriers can handle sorted bags of small parcels rather than handle all the individual packages at each node, which:

FedEx Ground has been using Berkshire Grey Robotic Product Sortation with Identification (BG RPSi) solutions in its Queens, NY, station to robotically sort the thousands of individual small parcels and packages that arrive daily bound for other regions. By pre-sorting to collection bags, FedEx is able to streamline the process of moving these packages through their network, ensuring timely customer deliveries are met nationwide. FedEx Ground also plans to install additional Berkshire Grey RPSi systems at sortation facilities in Las Vegas, Nev., and Columbus, Ohio, in the coming months.

During our recent webinar titled “Automate and Accelerate: Replacing Pick-to-Light with …

We are proud to share that Berkshire Grey has achieved SOC …

As warehouse operations evolve, the demand for efficient, scalable, and space-saving …

Contact the BG Fulfillment Automation Sales Engineering Team to Learn How to:

Call +1 (833) 848-9900

or connect using our form.