Trusted By Top Global Brands

Trusted by Top Global Brands

“Berkshire Grey took a very different approach to automation than we had seen from other

suppliers. BG invested the time necessary to understand our business, our operating

environments, and our culture. The project completion speed and early results are impressive.”

— Ray Daugherty, Bealls Senior Vice President, Logistics

INCREASES

PRODUCTIVITY

gains vs other approaches

AddressES Labor

Constraints

4X+ while reducing labor

requirements by up to 50%

IntegrateS into

ANY Warehouse

ready, with no disruptions

to your ongoing operations

Immediate ROI

cost per unit by ~40%

and buy under a Capex

or RaaS model

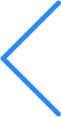

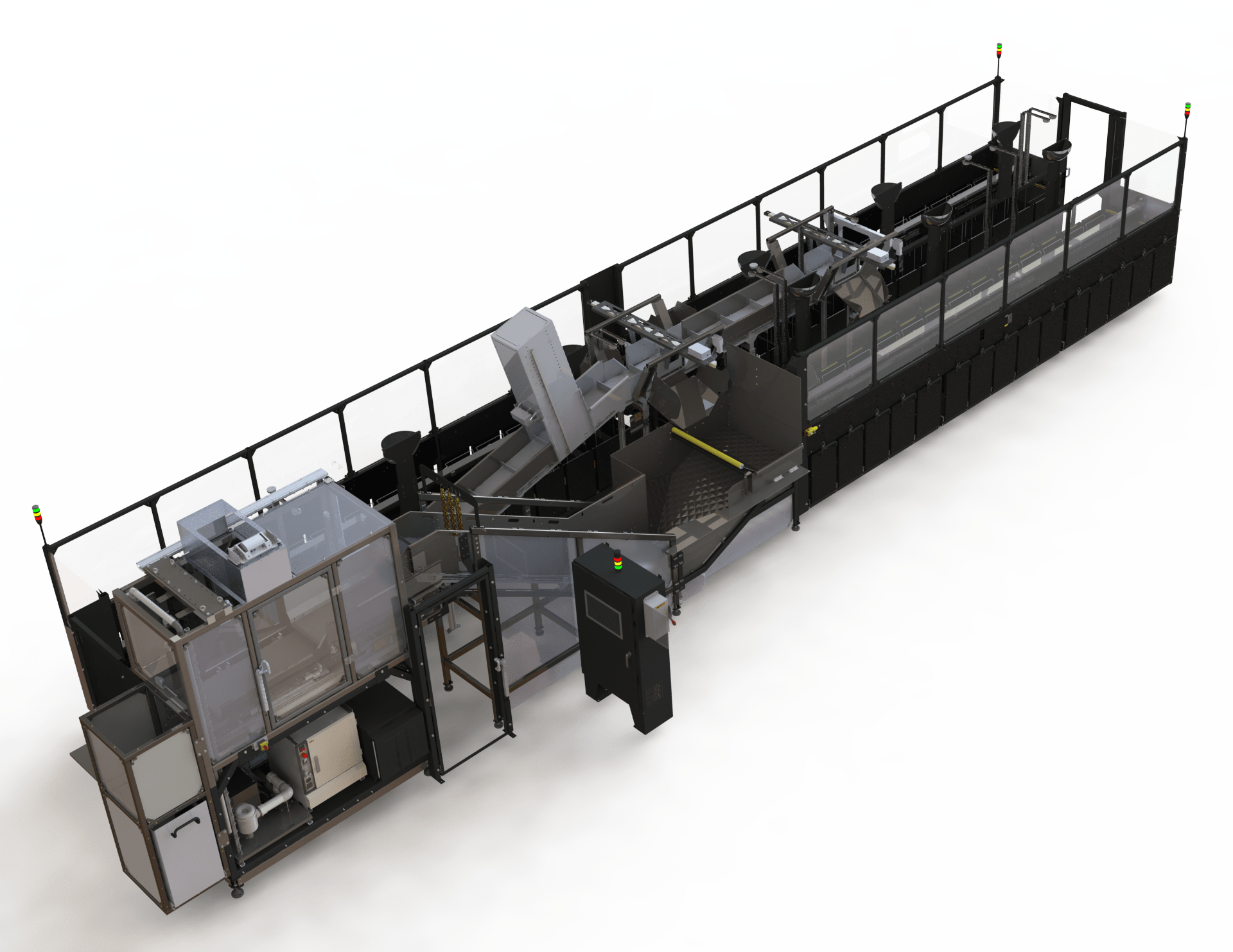

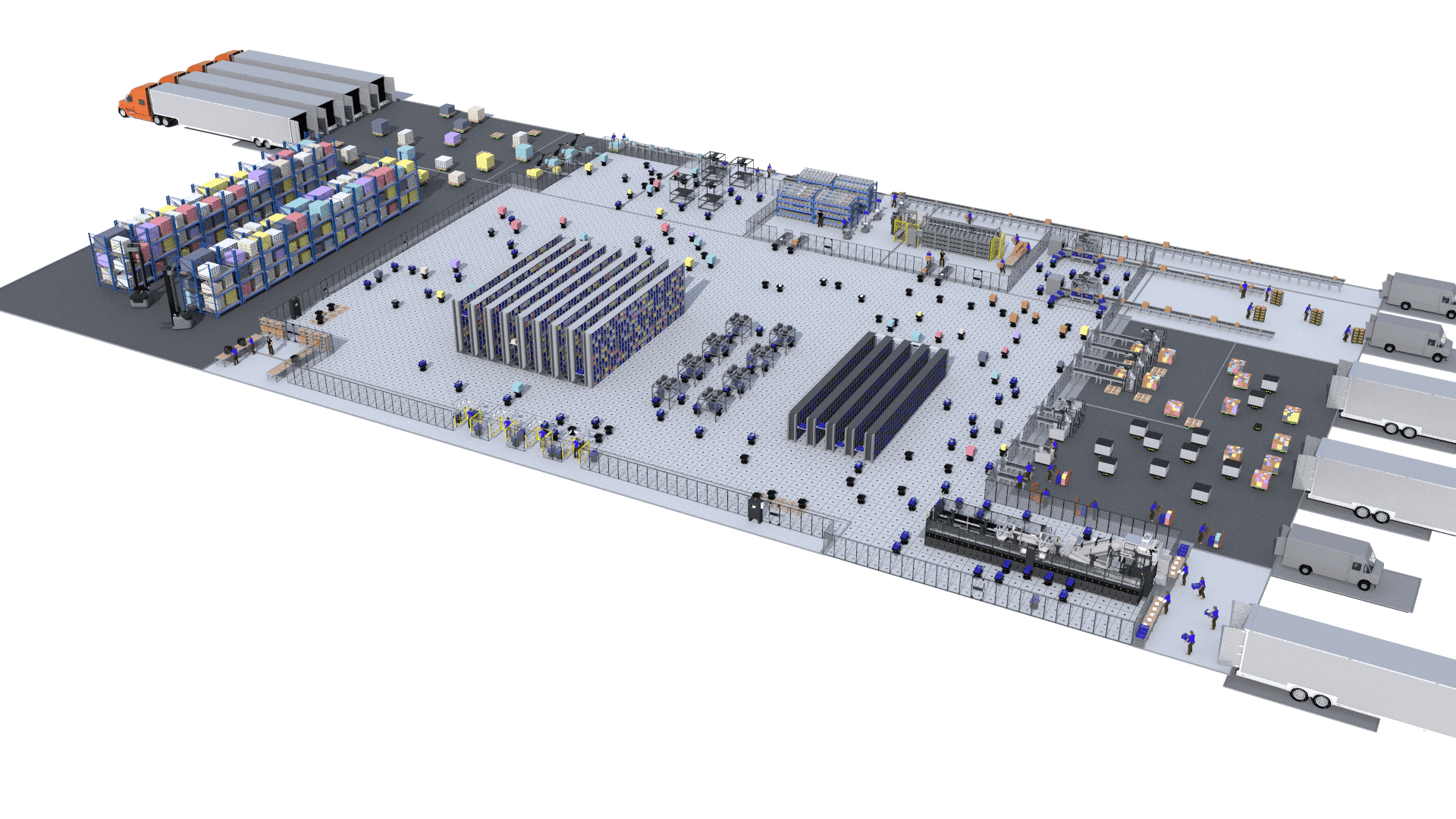

BG Automation Solutions That Work for Your Business

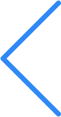

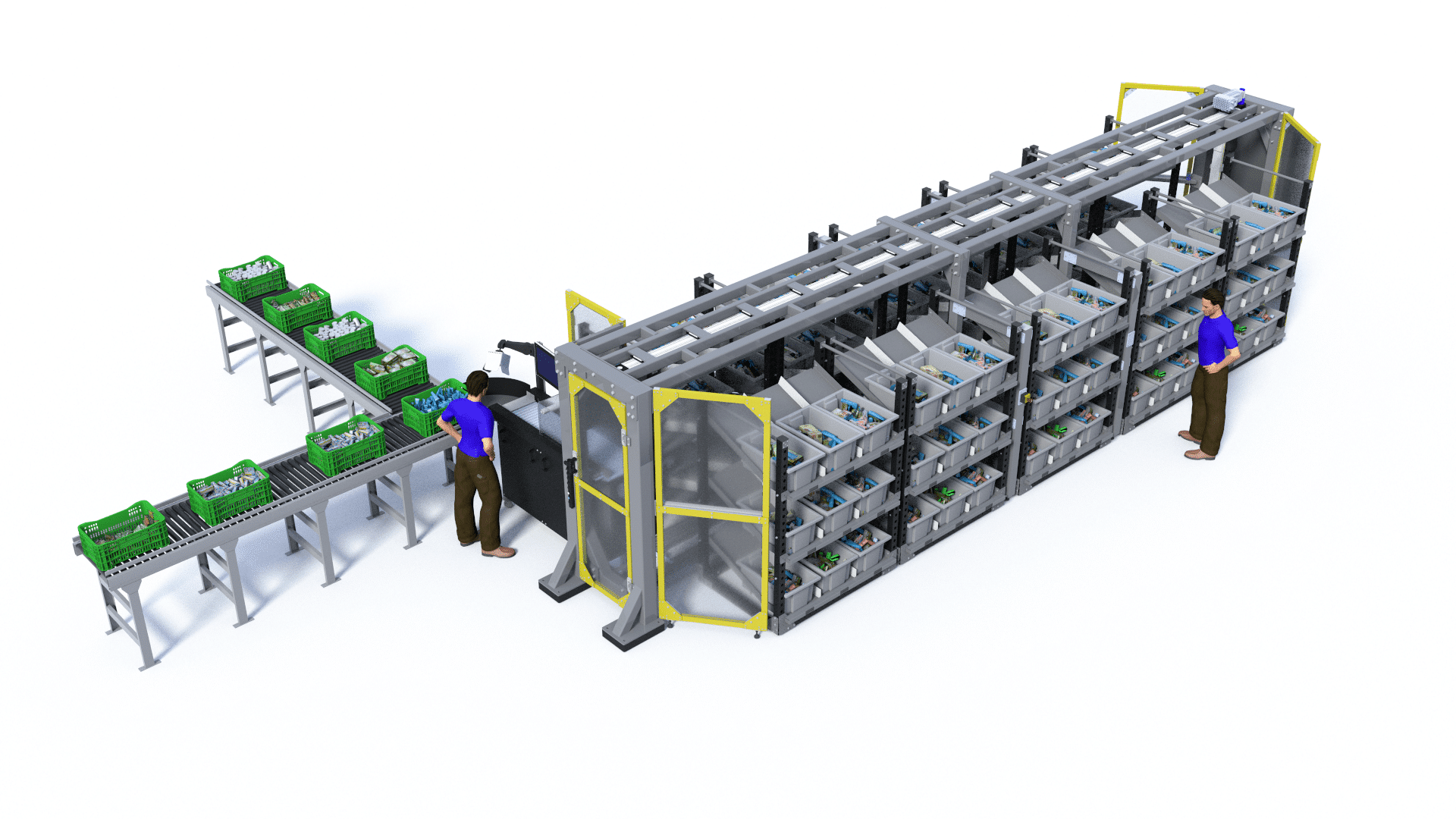

We automate manual supply chain tasks such as identifying, picking, sorting, packing, and moving.

Fulfilling Expectations for Our Customers

We help retail, eCommerce, package handling, and logistics companies deliver

great customer experiences while reducing the cost and time of fulfilling orders.

3X

Increased

Capacity

70%

Reduction in

Overhead Costs

90%

Reduction in

Truck Unload Times

How Can We Help Your Business?

Robotic automation from Berkshire Grey can accelerate your operations with increased performance, throughput, and less dependence on labor.

Tell us about your business challenges, and we’ll schedule a personalized demo of the right solutions for your needs along with a customized ROI analysis of your specific operations.