Robotic Sortation

Faster Store Replenishment and Omnichannel Fulfillment with Smart, Scalable Robotics

Legacy sorters cap your throughput and flexibility — BG Sortation doesn't

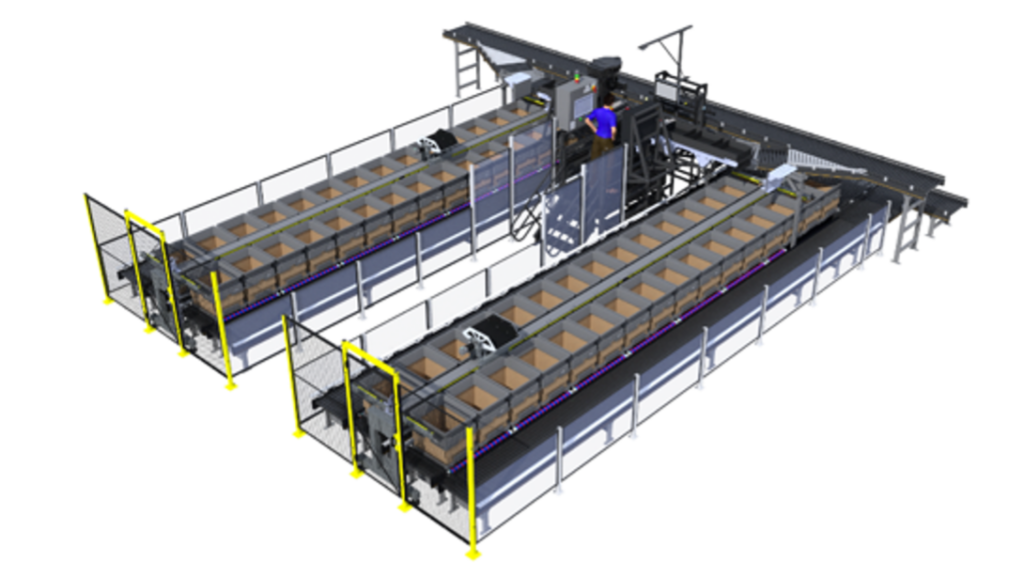

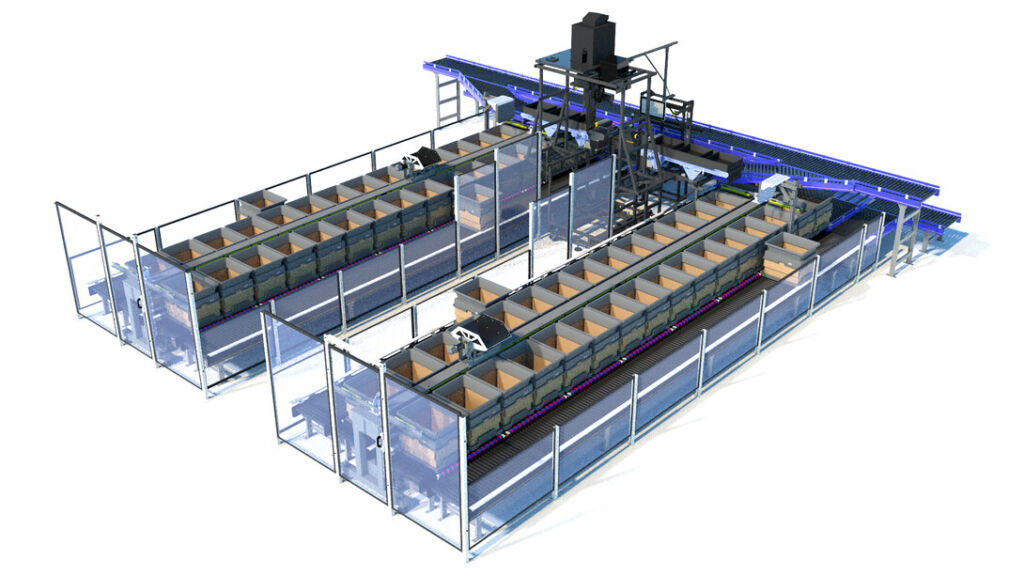

Our modular robotic sortation systems accelerate store replenishment and omnichannel fulfillment while reducing labor and reclaiming space, without disrupting existing operations.

The system integrates into current layouts and workflows, with configurable logic and modular hardware that expands throughput over time.

Proven in live production, it delivers measurable results with less labor, less space, and less complexity.

What's New

Middle Induct Boosts Throughput

Increases transfers per hour per cell — fewer pauses, faster flow.

New Beam Options Fit More Layouts

Shorter and longer beams = more destinations, better brownfield fit.

Updated UI Improves Ops Visibility

Real-time system view speeds decisions across shifts and teams.

Smarter Staffing, Built In

Match labor to demand with system-guided operator orchestration.

Robotic Product Sortation

Manual Picking

Robotic Picking

Modular robotic systems for store, wholesale, and eCommerce fulfillment.

Achieve 2,000+ units/hour and up to 284 destinations per module — with flexible, incremental scaling to meet demand. Supports both operator-led and robotic induction, with seamless orchestration of manual and robotic cells in one solution.

Designed for brownfield sites, with intuitive controls that improve visibility, productivity, and labor efficiency.

Top Global Retailers See Real-World Value

Fast Throughput, Lean Staffing

Achieve 2,000+ units/hour per module. Match labor to demand with flexible, guided staffing.

Compact Footprint, Flexible Deployment

Deploy in brownfield sites. Support 284 destinations per module with modular, scalable beams.

Minimal Disruption, Maximum Control

Maintain existing workflows. No WMS rebuilds or major process changes required.

Proven Reliability, Measurable Results

99.5% accuracy and 99%+ uptime. Built-in visibility and distributed reliability by design.

Customer Success Stories

FORTUNE 5 RETAILER

Customer Challenges: A leading retailer needed a solution to handle 3.5 million breakpack items monthly, requiring 10,000 labor hours. The challenge was intensified by labor shortages and the pandemic-driven surge in online demand.

Customer Solution: Berkshire Grey’s Robotic Sortation Systems automated store replenishment, allowing the retailer to increase volumes by 30% while reducing labor by 70%. The system operated 24/7, eliminating the need for an additional shift, and saved the retailer approximately $1 million annually in labor costs.

CUSTOMER VALUE

30%

Volume Increase

70%

Labor Cost Savings

FORTUNE 100 RETAILER

Customer Challenges: A leading discount retailer sought to replace their outdated unit sorter infrastructure with a modern, scalable solution capable of managing increasing volumes efficiently.

Customer Solution: Berkshire Grey’s Robotic Store Replenishment was deployed to transform their legacy system. It efficiently sorted all less-than-case quantity SKUs, including items previously incompatible with their old unit sorter, enabling higher throughput and operational efficiency.

CUSTOMER VALUE

50%

Capacity Increase

~3yr

Payback Projection

Learn More About Our Robotic Sortation Solutions

eBook

Dive in to our eBook to learn how robotic sortation can transform your warehouse operations and reduce labor costs.

Infographic

How BG robotic sortation speeds store replenishment and allocation processes while easing labor challenges

Case Study

A Fortune 5 retailer increased store replenishment volumes by 30% without adding labor